Description

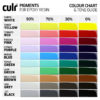

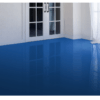

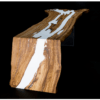

Incredible pigments for epoxy resin art, counter-tops and floors

Super Concentrated

Up to 5kg (5 litres) of epoxy resin can be coloured using a singe 20ml bottle of CULR™ pigment, making them the most concentrated resin pigments available whilst the advanced liquid formula ensures that these intense pigments disperse in seconds. Better still, the concentration of these vibrant liquid pigments and the special epoxy-compatible carrier means that your pigmented resin will still cure with a pristine surface.

The exact amount of pigment needed will vary depending on the colour and intensity required but will be between 0.2 and 1%.

Blend to Create any Colour

For resin artists creating flow art -type pieces or makers wishing to create realistic multi-tone marble / stone coat effects, CULR pigments have been developed to work together as a complete colour system, allowing almost any colour to be created simply by blending any of the 8 foundation colours whilst adding drops of white or black can adjust the saturation and brightness to create infinite possibilities.

Very often, Super White is added to other colours to change their saturation and opacity. See the Tone Chart image for each colour to see the effect of adding a few drops of white to each colour.

Metallic Colours

The CULR range also includes 3 metallic colours of copper, silver and gold which can be used on their own or blended with other CULR pigments to achieve even more unique colour effects. Owing to their different density, the metallic CULR pigments behave differently in resin compared to the SHIMR metallic powder pigments, generally the metallic particles in the CULR pigments will rise to the top of resin, rather than sinking into it, creating a metallic effect which seems to sit above the other colours.

Metallic colour sets contain: Polished Copper, Polished Silver, Polished Gold

How to Use

CULR™ pigments are super-easy to use; just drip the desired amount of any colour into either mixed resin and hardener or into just the resin side only (if you want to pigment the resin in advance of using it).

Depending on the strength of the colour required and the actual colour you’re using, you’ll need between 0.1% and 1% of pigment. The table below gives you an easy reference as to how much pigment to add or simply keep adding drops until you get the desired colour strength. Remember that CULR pigments are super-concentrated and so you only need a tiny amount to achieve stunning, vivid colours.

| Amount of resin | 20g | 50g | 100g | 1kg | 5kg |

| Minimum pigment | 2 drops | 4 drops | 7 drops | 2g | 10g |

| Maximum pigment | 7 drops | 17 drops | 34 drops | 10g | 50g |

For Red, Yellow and White

| Amount of resin | 50g | 100g | 1kg | 5kg | 32kg |

|---|---|---|---|---|---|

| Translucent tint | < 1 drop | 1 drop | 6 drops | 30 drops / 1.5g | 10g |

| Solid opaque colour | 40 drops / 2.5g | 4g | 40g | 200g | 1200g |

Some of the bright colours (such as Tangy Yellow and Tomato Red) are so pure and bright that they will remain slightly translucent, even at higher concentrations. To make these colours opaque, simply add a small amount of Super White.

Compatibility

CULR pigments are designed specifically for use with clear epoxy resins. They have been thoroughly tested with the GlassCast range of casting and coating resins but should also work with most other clear epoxy systems, although we always recommend conducting a test first.

CULR pigments are not suitable for use with alternative resin types such as polyurethane.